Description of Harmonic Drive Servo Rotary Actuators

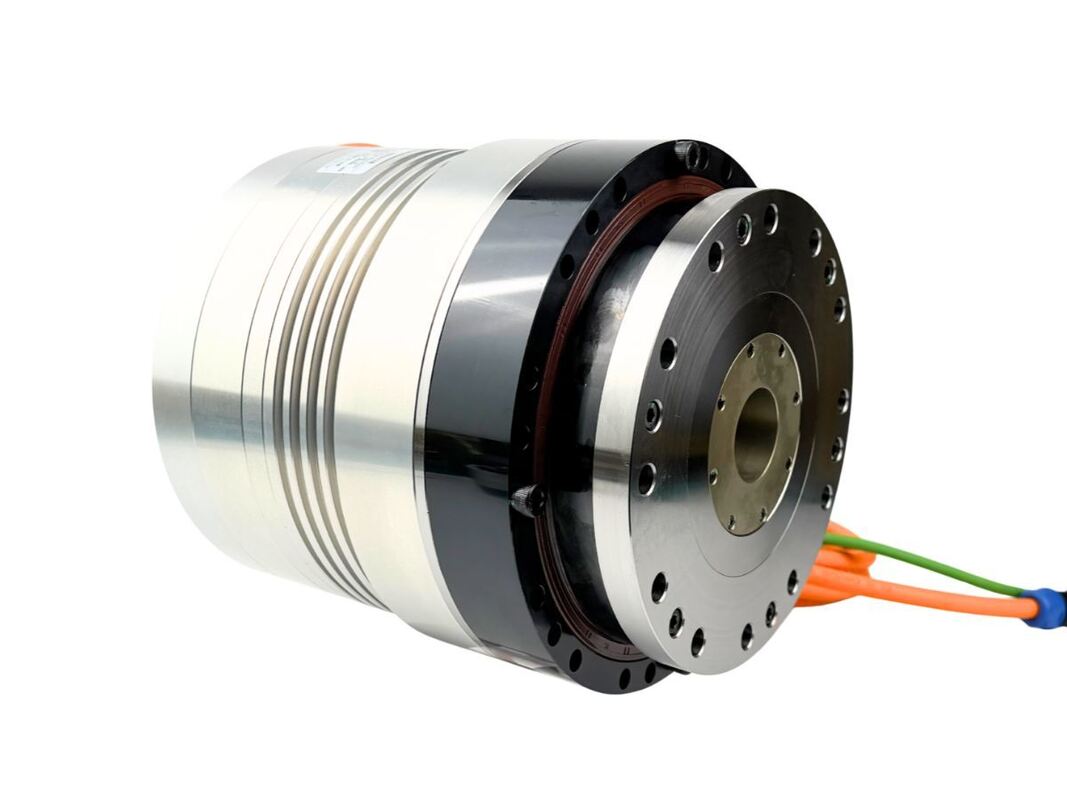

The HAT Hollow and Standard Harmonic Servo Rotary Actuators are compatible with harmonic drives of models 11, 14, 17, 20, 25, 32, 40, 50, and 58. They deliver rated torques ranging from 4 N·m to 1200 N·m and can accommodate outer diameters between 62 mm and 220 mm. These actuators are equipped with multi-turn absolute encoders adhering to the Tamagawa protocol, offering configurations such as single-turn 17-bit with multi-turn 16-bit, or single-turn 23-bit with multi-turn 16-bit. Custom dual-encoder setups can also be provided. Their design allows for direct mounting through the end face, making them particularly suitable for applications where weight or space is limited.

Features of Harmonic Drive Servo Rotary Actuators

Hollow Bore Design

The hollow core allows for the passage of motor cables, sensor wires, or hydraulic/pneumatic lines through the joint. This design eliminates the risk of exposed lines becoming tangled, making it ideal for collaborative robots, multi-joint robotic arms, and other serial-link systems.

Compact Integration

The motor, encoder, and brake are seamlessly combined into a single, compact unit, facilitating quick connections to drives and streamlining overall system integration.

Durability and Low Maintenance

The gear teeth are designed to wear evenly, preventing harsh impacts, and ensuring tens of thousands of hours of operation under typical conditions. With minimal lubrication and upkeep required, this design helps lower long-term operating expenses.

Robust Environmental Performance

These actuators function reliably in dusty or humid conditions. Certain high-performance models can operate within an extensive temperature range of -40°C to 70°C, making them suitable for industrial environments, outdoor applications, and other demanding situations.

Versatile Operation

Engineered for challenging weight and space requirements, the actuators facilitate a lightweight design and enhanced motion flexibility, thus improving overall equipment performance.

Specification of Harmonic Drive Servo Rotary Actuators

| Model |

|

HAT11 |

HAT14 |

HAT17 |

HAT20 |

HAT25 |

HAT32 |

HAT40 |

HAT50 |

HAT58 |

| Reduction Ratio |

/ |

51 |

101 |

51 |

81 |

101 |

51 |

81 |

101 |

121 |

51 |

81 |

101 |

121 |

161 |

51 |

81 |

101 |

121 |

161 |

51 |

81 |

101 |

121 |

161 |

51 |

81 |

101 |

121 |

161 |

51 |

101 |

51 |

101 |

| Rated Torque |

N·M |

4 |

8 |

8.6 |

13.5 |

13.5 |

27 |

33 |

49 |

49 |

30 |

48 |

58 |

61 |

61 |

68.5 |

107 |

133 |

133 |

133 |

133 |

206 |

264 |

267 |

267 |

242 |

351 |

460 |

557 |

557 |

642 |

823 |

951 |

1200 |

| Peak Torque |

N·M |

8.3 |

11 |

23 |

29 |

34 |

43 |

53 |

66 |

66 |

69 |

91 |

102 |

108 |

113 |

121 |

169 |

194 |

207 |

217 |

267 |

376 |

411 |

436 |

459 |

497 |

641 |

702 |

762 |

800 |

1163 |

1211 |

1828 |

1964 |

| Rated Speed |

RPM |

69 |

35 |

59 |

37 |

30 |

59 |

37 |

30 |

25 |

59 |

37 |

30 |

25 |

19 |

49 |

31 |

25 |

21 |

16 |

45 |

28 |

23 |

19 |

14 |

39 |

25 |

20 |

17 |

12 |

27 |

22 |

27 |

22 |

| Max Speed |

RPM |

102 |

51 |

118 |

74 |

59 |

118 |

74 |

59 |

50 |

118 |

74 |

59 |

50 |

37 |

94 |

59 |

48 |

40 |

30 |

90 |

57 |

49 |

38 |

29 |

80 |

51 |

41 |

34 |

25 |

37 |

30 |

37 |

30 |

| Rated Current |

A |

0.98 |

0.99 |

0.78 |

0.77 |

0.62 |

2.36 |

1.82 |

2.17 |

1.81 |

2.63 |

2.65 |

2.56 |

2.25 |

1.69 |

3.90 |

3.84 |

3.83 |

3.20 |

2.40 |

5.82 |

5.68 |

5.83 |

4.93 |

3.7 |

8.72 |

7.97 |

8.37 |

8.46 |

6.36 |

11.94 |

12.27 |

17.68 |

17.89 |

| Max Current |

A |

2.03 |

1.36 |

2.09 |

1.66 |

1.56 |

3.68 |

2.92 |

2.92 |

2.44 |

6.04 |

5.02 |

4.51 |

3.98 |

3.13 |

6.90 |

6.07 |

5.58 |

4.97 |

3.92 |

11.69 |

10.36 |

9.08 |

8.04 |

6.36 |

17.91 |

14.55 |

12.75 |

11.58 |

9.13 |

21.62 |

18.06 |

33.99 |

29.29 |

| Torque Constant |

N·M/Arms |

4.08 |

8.08 |

11.02 |

17.50 |

21.82 |

11.42 |

18.14 |

22.62 |

27.10 |

11.42 |

18.14 |

22.62 |

27.10 |

36.06 |

17.54 |

27.86 |

34.74 |

41.62 |

55.38 |

22.85 |

36.29 |

45.25 |

54.21 |

72.13 |

27.74 |

44.06 |

54.94 |

65.82 |

87.58 |

53.78 |

67.06 |

53.784 |

67.064 |

| Unidirectional Positioning Accuracy |

Arcsec |

≤90 |

≤90 |

≤70 |

≤60 |

≤60 |

≤60 |

≤60 |

≤50 |

≤50 |

≤60 |

≤60 |

≤60 |

≤50 |

≤50 |

≤60 |

≤50 |

≤50 |

≤40 |

≤40 |

≤60 |

≤50 |

≤50 |

≤40 |

≤40 |

≤60 |

≤50 |

≤50 |

≤40 |

≤40 |

≤30 |

≤30 |

≤30 |

≤30 |

| Repeat Positioning Accuracy |

Arcsec |

≤20 |

≤20 |

≤15 |

≤10 |

≤10 |

≤15 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

| Tilt Stiffness |

X104N.m/rad |

4 |

8 |

15 |

24 |

38 |

95 |

175 |

Rated radial load 2750N

Rated axial load 2750N

Rated overturning moment 1950N.M |

Rated radial load 3200N

Rated axial load 3200N

Rated overturning moment 2500N.M |

| Torsional Stiffness |

X104N.m/rad |

0.3 |

0.34 |

0.46 |

0.6 |

1.07 |

1.3 |

1.8 |

2.3 |

3.4 |

4.6 |

7.6 |

9.9 |

14 |

18.6 |

| Motor Phase Resistance |

Ohma(20°C) |

12 |

7.5 |

2.6 |

2.6 |

3.55 |

0.88 |

0.8 |

0.126 |

0.126 |

| Motor Phase Inductance |

Mh |

9.5 |

11.5 |

6.7 |

6.7 |

10 |

6.1 |

8 |

0.65 |

0.65 |

| Back-EMF Constant |

Vrms/Krpm |

10.5 |

25 |

25 |

25 |

40 |

40 |

44 |

52 |

52 |

| Rotor Inertia |

Without brake KG*m2 |

8.32*10^-6 |

3.6*10^-5 |

7.96*10^-5 |

8.8*10^-5 |

2.1*10^-4 |

8.3*10^-4 |

1.64*10^-3 |

4.8*10^-3 |

4.8*10^-3 |

| Rotor Inertia |

With brake KG*m2 |

8.73*10^-6 |

3.7*10^-5 |

9.12*10^-5 |

9.17*10^-5 |

2.2*10^-4 |

1.04*10^-3 |

2.05*10^-3 |

/ |

/ |

| Mass (Without Brake) |

Kg |

1.17 |

1.66 |

2.2 |

2.4 |

3.6 |

7.4 |

10.7 |

25 |

32 |

| Mass (With Brake) |

Kg |

1.36 |

2 |

2.8 |

2.96 |

4.2 |

8.7 |

12 |

/ |

/ |

| Motor Poles |

Pole |

10 |

16 |

16 |

16 |

16 |

16 |

16 |

20 |

20 |

| Diameter & Length (With/Without Brake) |

mm |

63mmX83mm

63mmx99.7mm |

ø74mmX91.5mm

ø74mmX109.5mm |

ø88mmX98mm

ø88mmX122mm |

ø88mmX101mm

ø88mmX125mm |

ø110mmX109mm

ø110mmX130.5mm |

ø142mmX138.7mm

ø142mmX164.2mm |

ø170mmX150.7mm

ø170mmX175.7mm |

ø214mmX196mm |

ø240mmX216mm

ø240mmX249.4mm |

| Hollow Shaft Diameter |

mm |

ø10mm |

ø9mm |

ø13.5mm |

ø16.5mm |

ø17mm |

ø29mm |

ø40mm |

ø40mm |

ø50mm |

| Notes |

For reference only, please contact sales for actual parameters |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!